The peculiarities of etching according to the type of steel: cold-rolled or stainless.

For our armour and accessories we use two types of metal: stainless steel and mild (cold-rolled) steel. The result of etching significantly depends on the chosen type.

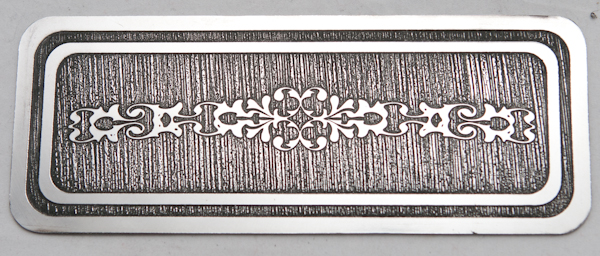

Etching the cold-rolled steel results in deeper but less notable image. Though the depth of the motif is bigger then in case of stainless steel, the etched area has the same texture as the non-etched surface.

It is more complicated to etch the stainless steel, so the resulting image is not as deep as in the case of mild steel. However the texture of etched stainless area has so called shagreen - an unusually rough and granular surface - that stands in contrast to the shining non-etched steel and gives brighter image.

Moreover the etched cold-rolled steel rusts very easily and is rather difficult to maintain because of it's detailed surface topography and roughness. So this option is suggested for 80th level reconstructors only :) / for highly motivated reconstructors.

Etched mild steel - deeper releif but less contrast

Etched stainless steel - strong contrast but less deep relief